The transformation of manufacturing through technology is marked by significant advancements in automation, artificial intelligence, and connectivity. These innovations enable manufacturers to optimize processes and enhance productivity while reducing costs. Smart factories exemplify this shift, utilizing real-time data for decision-making and predictive maintenance. As advanced robotics increasingly collaborate with human workers, the implications for workforce dynamics become evident. This evolution raises questions about future industry standards and competitive strategies.

The Rise of Automation in Manufacturing

As industries increasingly embrace technological advancements, the rise of automation in manufacturing has become a pivotal trend reshaping production processes.

Smart factories exemplify this shift, utilizing interconnected systems to enhance efficiency and productivity.

Automation benefits include reduced operational costs and increased precision, allowing manufacturers to respond swiftly to market demands while ensuring high-quality outputs.

This transformation fosters greater independence and adaptability in the manufacturing landscape.

See also: prono-choc

Embracing Artificial Intelligence for Enhanced Decision-Making

While the integration of artificial intelligence (AI) in manufacturing processes may seem daunting, its potential to enhance decision-making is becoming increasingly evident.

By leveraging data analytics, manufacturers can derive actionable insights, optimize operations, and improve efficiency.

Additionally, AI-driven predictive maintenance allows companies to anticipate equipment failures, reducing downtime and costs.

This transformative approach empowers organizations to make informed, strategic decisions, fostering greater autonomy in a competitive landscape.

The Impact of the Internet of Things on Production Processes

The Internet of Things (IoT) is revolutionizing production processes by enabling seamless connectivity between machines, devices, and systems.

This integration fosters the development of smart factories, where real-time data analytics enhance operational efficiency. Additionally, IoT facilitates predictive maintenance, allowing manufacturers to anticipate equipment failures and minimize downtime.

Consequently, these advancements empower businesses to optimize resources and achieve greater flexibility in production.

Advanced Robotics: Redefining Workforce Dynamics

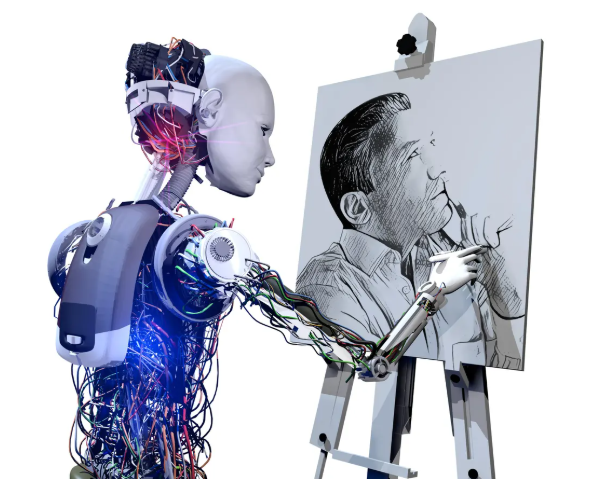

How are advanced robotics reshaping the dynamics of the manufacturing workforce?

The integration of collaborative robots enhances productivity by enabling seamless workforce integration, allowing human workers to focus on complex tasks.

Data indicates that companies adopting these technologies experience a significant reduction in operational costs and increased efficiency.

As a result, advanced robotics not only optimize processes but also redefine employee roles in manufacturing environments.

Conclusion

In conclusion, the integration of technology in manufacturing not only streamlines processes but also redefines the industry’s landscape. As automation and AI enhance operational efficiency, one must ponder: can manufacturers afford to ignore these advancements in an increasingly competitive market? The data clearly indicates that adaptability and innovation are no longer optional; they are essential for survival. Embracing these technological transformations will determine the future trajectory of manufacturing, positioning companies for sustained success amidst evolving challenges.